Blister machines are widely used for packaging in the food, pharmaceutical, and cosmetic industries.

Blister machine is now widely used in the pharmaceutical industry, one of the rapidly developing forms of flexible packaging of drugs, and is gradually replacing the traditional glass bottle packaging and bulk packaging, becoming the mainstream of solid drug packaging. Compared with bottles, blister packaging has the advantage of easy portability, which can avoid the contamination of drugs in the process of carrying and taking, in addition, blister packaging also has obvious advantages in gas barrier, moisture resistance, safety, production efficiency, dose accuracy, etc.

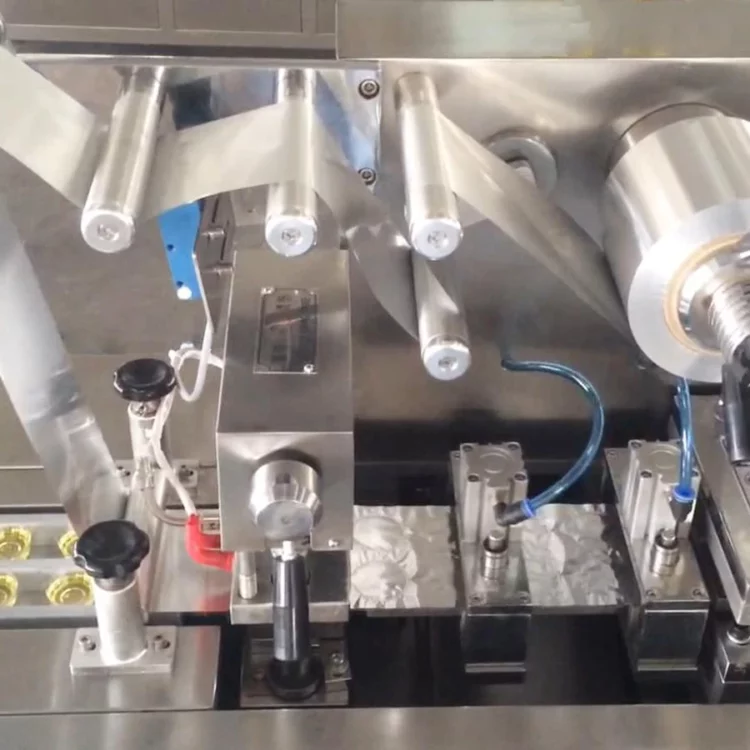

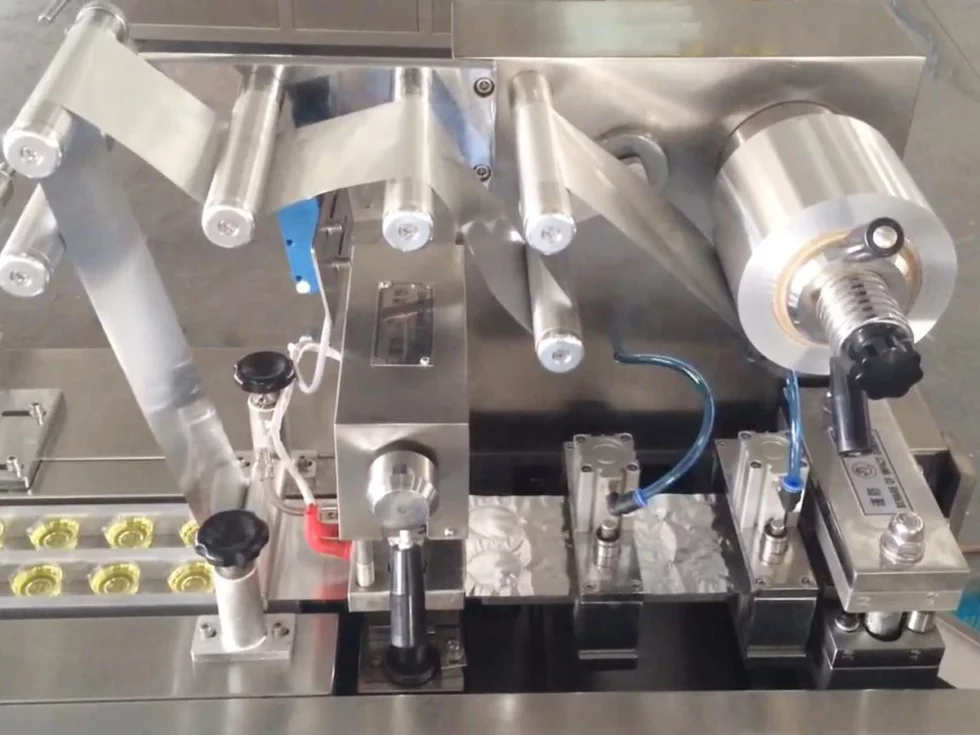

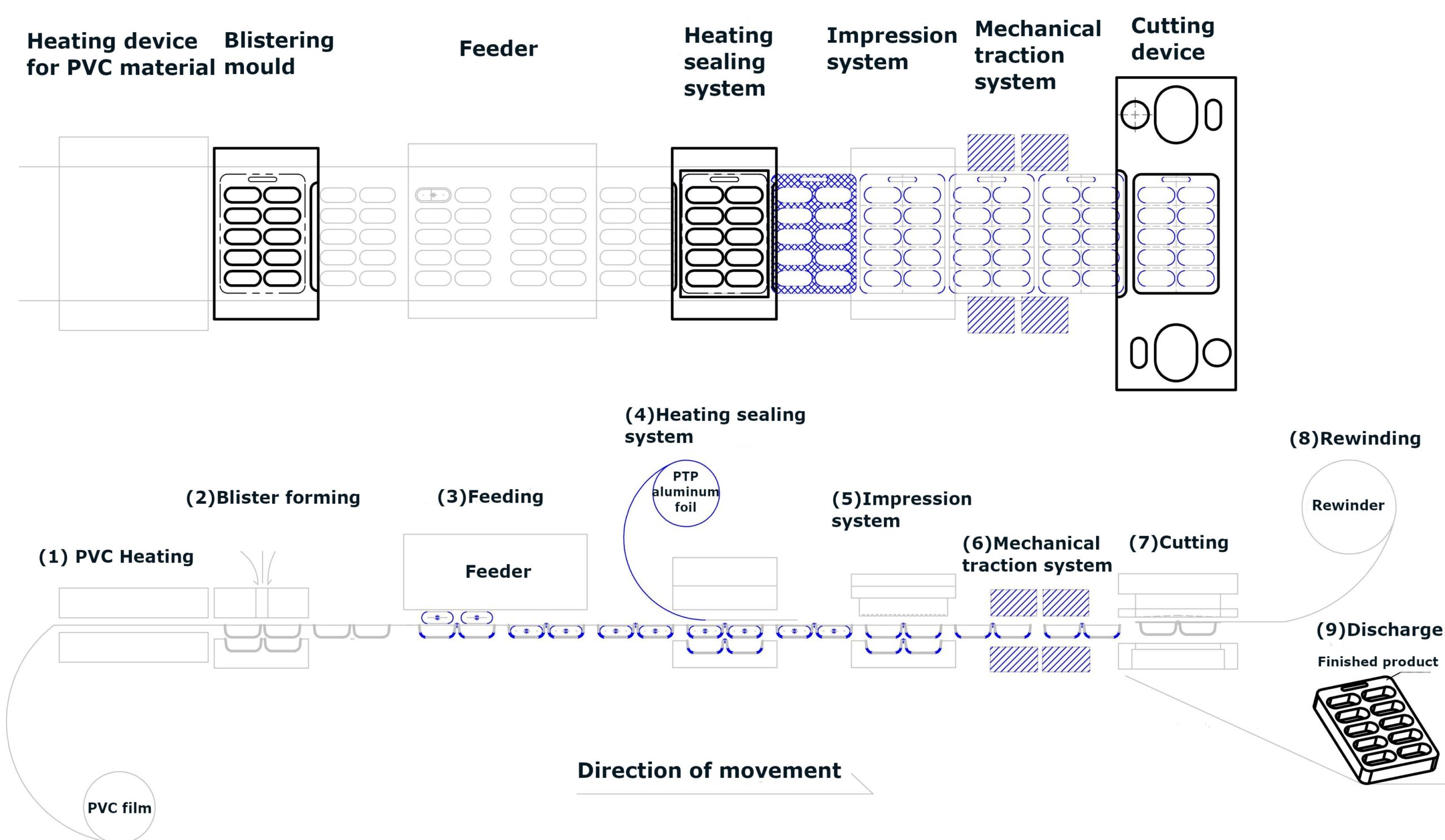

The blister machine adopts PLC programmable control, frequency conversion speed control, servo motor traction, the traction length can be adjusted arbitrarily within the technical parameters within the touch screen program, avoiding the error caused by manual mechanical adjustment, thus greatly reducing the labor intensity and waste of consumables.

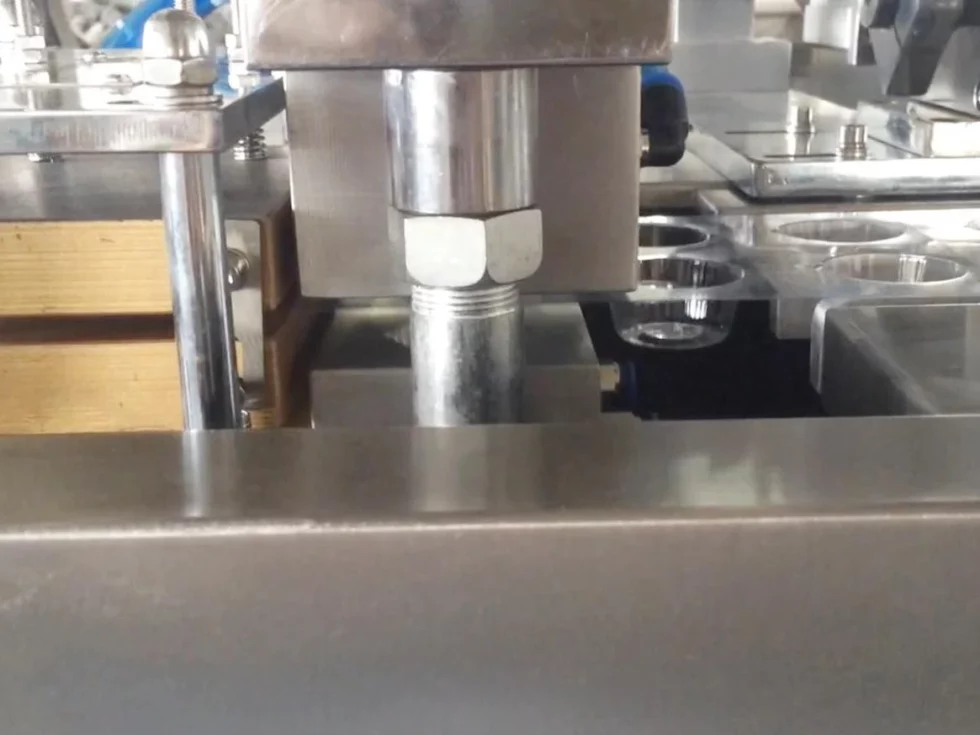

At present, the basic production process of blister machine is: after blistering and molding the transparent plastic hard sheet, the tablets, pills or granules, capsules and other solid drugs are filled in the groove, and then heated and bonded together with the aluminum foil coated with adhesive, thus forming an independent sealed package.

Due to the advantages of blister machine, this type of machine has been widely used in the packaging of food, pharmaceutical, cosmetic and other industries.