The SBMHS-240 Horizontal Form, Fill and Seal (HFFS) Sachet, Flat pack Packing Machines are high-performance machines that eliminate the need for pre-made bags by using laminated roll stock film to create a large variety of flat pouch styles and reduce material cost dramatically. As opposed to purchasing pre-made pouches, cost savings of up to 30% may be incurred by producing a finished product in these machines.

- Home

- HFFS Machines

- HFFS Flat Pack Packing Machine SBMHS-240

HFFS Flat Pack Packing Machine SBMHS-240

01 Overview

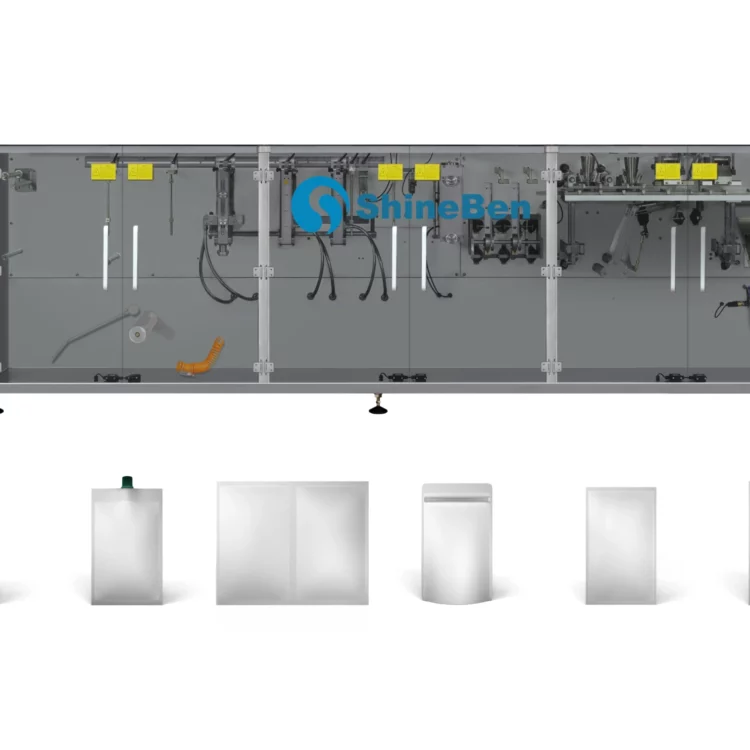

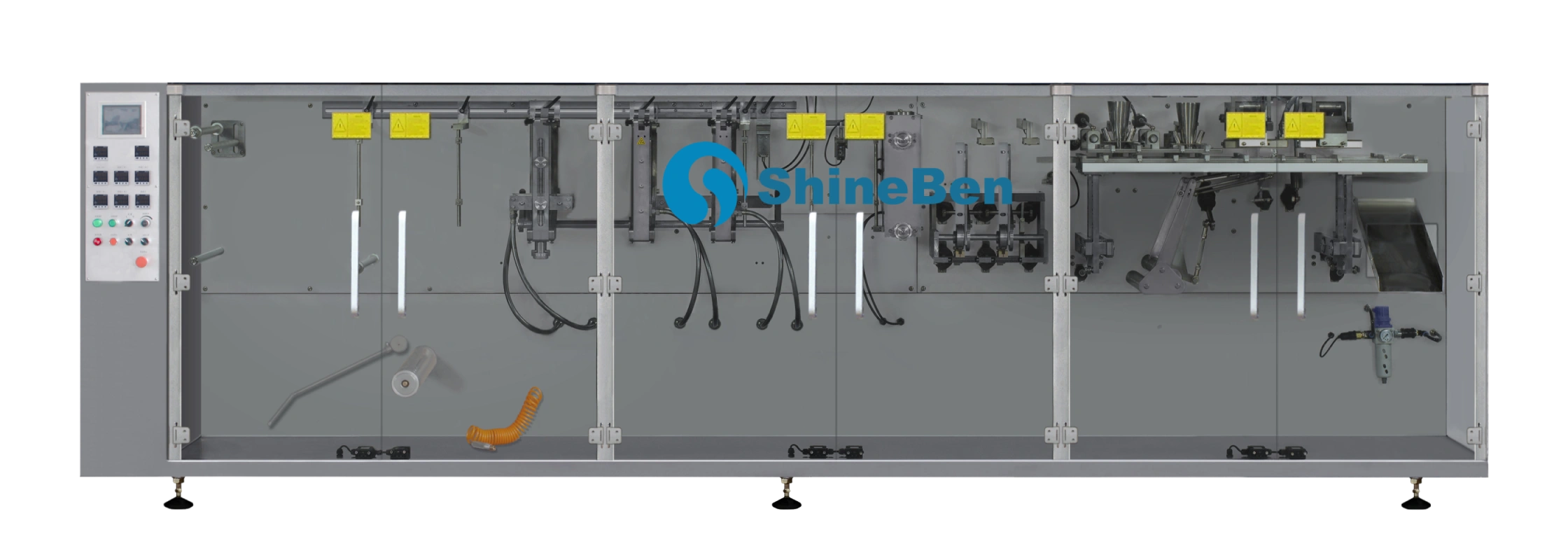

The SBMHS-240 HFFS flat pack packing machine is one of the larger machines in the SBMHS series and makes, fills, and seals the 3-side and 4-side sealed bags or Flatpacks, mold-cut shaped pouches, or flat spout pouches of premium quality and appearance.

02 Flat Pack Packing Machine Description

03 Bag Styles

The SBMHS-240 HFFS flat pack packing machine is one of the larger HFFS machines in the SBMHS series and makes, fills, and seals the 3-side and 4-side sealed bags or Flatpacks, mold-cut shaped pouches, or flat spout pouches of premium quality and appearance.

04 Technical Data

| Parameter | SBMHS-240 | SBMHS-240Z | SBMHS-240C |

|---|---|---|---|

| Pouch Type | Flat Pouch, Shaped, Hanging Hole | Flat Pouch, Shaped with Zipper, Hanging Hole | Flat Pouch, Shaped, Spout Pack |

| Packing Material | All kinds of laminated films | All kinds of laminated films | All kinds of laminated films |

| Min Pouch Size(W × L) | 100mm×120mm | 100mm×120mm | 100mm×120mm |

| Max Pouch Size(W × L) | 240mm × 320mm | 240mm × 320mm | 240mm × 320mm |

| Max Volume | 1000ml | 1000ml | 1000ml |

| Max. Packing Speed | 60-80 bags/min | 60-80 bags/min | 60-80 bags/min |

| Number of Filling Station | 2 | 2 | 2 |

| Standard Functions | Date Printing, Output Conveyor | Date Printing, Output Conveyor | Date Printing, Output Conveyor |

| Optional Functions | No-bag-no-fill, Aseptic packing, Antistatic, CIP, Anti-dropping filling | No-bag-no-fill, Aseptic packing, Antistatic, CIP, Anti-dropping filling | No-bag-no-fill, Aseptic packing, Antistatic, CIP, Anti-dropping filling |

| Air Consumption | 350NL/min | 400NL/min | 400NL/min |

| Ambient Temperature | -10°C~55°C | -10°C~55°C | -10°C~55°C |

| Relative Humidity | Below 85%(Non condensation) | Below 85%(Non condensation) | Below 85%(Non condensation) |

| Power Consumption | 5.5 kw | 6.5 kw | 6.5 kw |

| Supply Voltage | 220V, 3 Phase, 50/60Hz | 220V, 3 Phase, 50/60Hz | 220V, 3 Phase, 50/60Hz |

| Dimension(L × W × H) | 3900mm × 970mm × 1450mm | 4500mm × 970mm × 1450mm | 4500mm × 970mm × 1450mm |

| Weight | 2000 kg | 2200 kg | 2200 kg |

05 Options

Filler Options

- Auger Filler ( for powder products)

- Volumetric Cup Filler (for grains)

- Multi-head Weigher (for grains and granular items like chips, candies etc.)

- Piston Pump ( for liquid products)

- Tablet Counting (for tablets)

- Vibrating Filler ( for block items, nails, screws, etc.)

Machine Options

- Hole punch device

- Gas flush device

- Middle capping device

- The shaped bag molding device

- Stand-up pouch former

- Tear notch device

- Zipper application device

- Vacuum station etc. are among many options available

Machine Material Options

- SS304 stainless steel based product contact parts for general food/cosmetics/pharmaceutical industries

- SS316 corrosion-resistant stainless steel based product contact parts for highly corrosive products like salt, chemicals, etc.

Optional Equipment

- Screw elevator/conveyor for automatic continuous feeding of powder products

- Z-bucket elevator for automatic continuous feeding of granular products

- Agitator/mixer for liquid or paste products

- Product counter and stacking belt conveyor

- Extra filler equipment for different powder, granular, liquid, or part type products packaging in a single machine. The choices are: volumetric cup filler, multi-head weigher, piston pump filler, auger filler, and vibrating filler

- Air compressor

- Complete line including Meta Detector, Check Weigher, Boxing or Cartoning Machine, Robot Palletizer, Pallet Wrapping Machines, etc.

06 Order Inquiry

Contact Us for a Quote on the HFFS flat pack Packing Machine

Do you have a specific question? Whether you’re an existing customer or potential new customer to Shineben, please fill out the attached form and we will respond to your request in a timely manner.