The machine is a rugged, mechanical, automatic horizontal cartoning machine for erecting, loading, and closing end load cartoner at speed of up to 100 cartons per minute. This cartoner excels in terms of cost-efficiency, precision, and process reliability. It’s suitable for food, dairy, blister, pouch, home goods, cosmetics, hardware, electronic parts, pharmaceutical products, and so on.

The cartoner can be integrated into a line or used as a standalone machine. Tuck-in and hot-melt closures are available depending on your requirement. Moreover, this machine can be fitted with marking systems or Track &Trace functions and can be linked to the appropriate labeling machines.

Its method of operation is as follows:

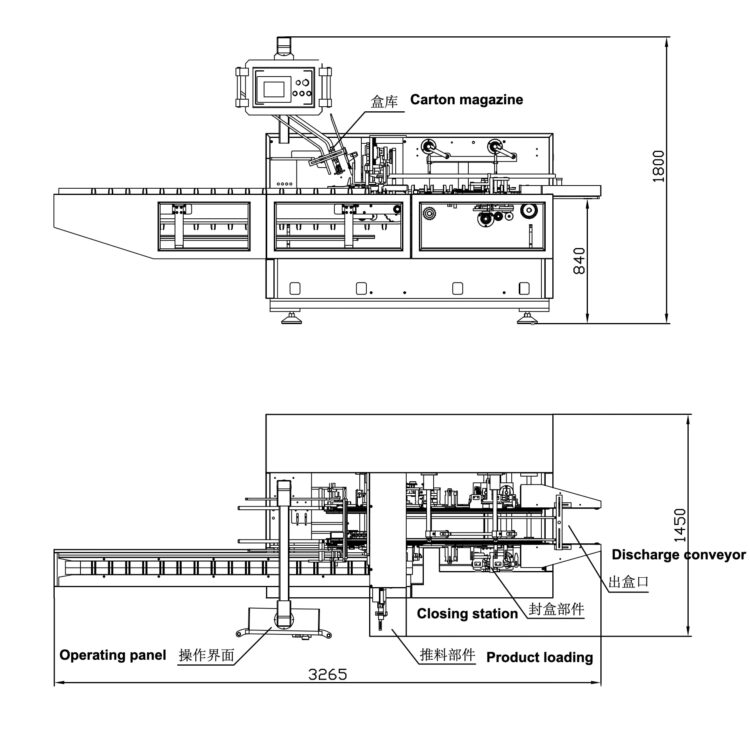

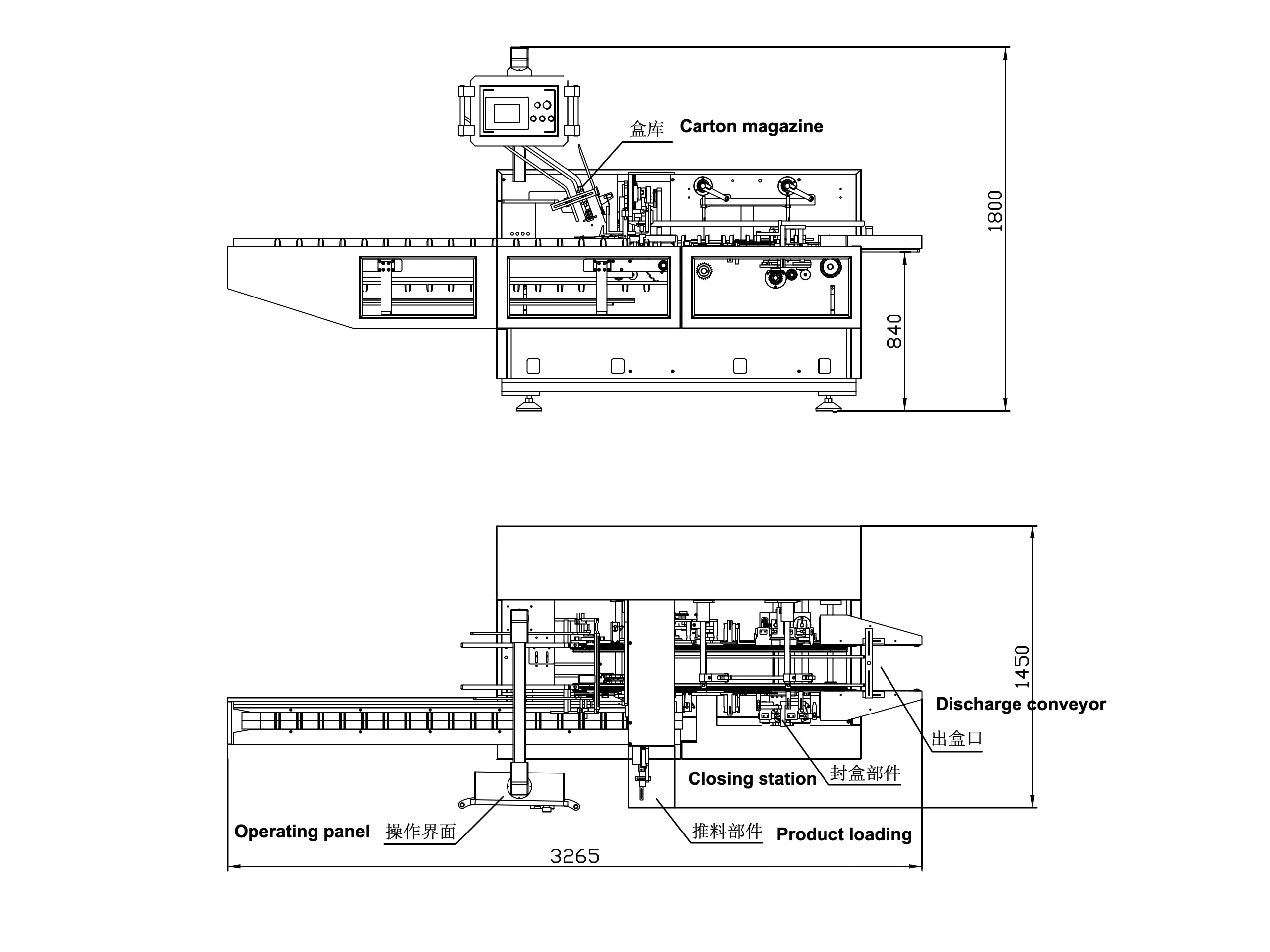

- The end-load carton is removed from a supply magazine via a vacuum system.

- Carton is erected at the carton opening station.

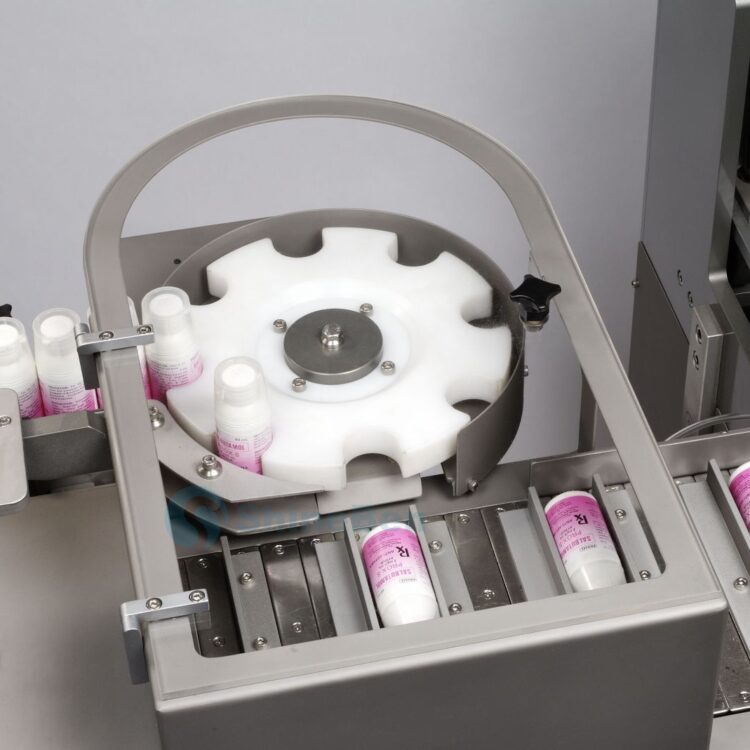

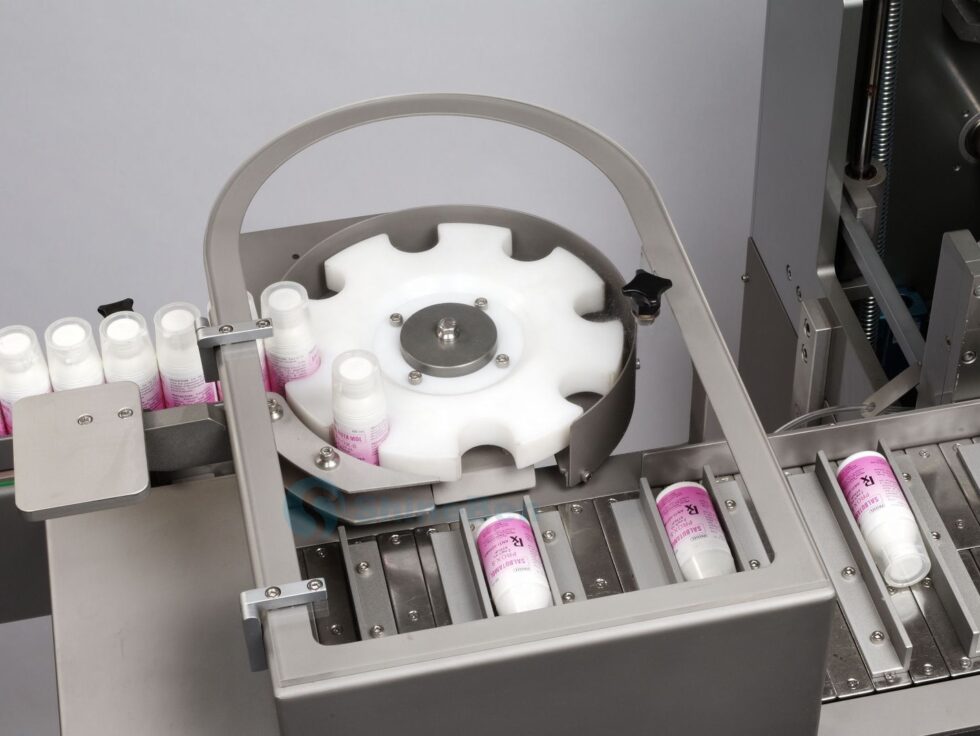

- The product is automatically horizontally loaded into a carton.

- The loaded carton is transported to the closing position for tuck-in or hot-melt closure.

- A completed carton is then automatically delivered from the machine to a convenient working height.

Features of the side load cartoning machine

- Powered carton supply magazine with low-level indicator.

- Sanitary Construction (essentially stainless steel), as per GMP rules

- Compact footprint

- Intermittent motion

- Simple, quick size changeover

- Mechanical parts in an oil bath to reduce maintenance and extend the life of drive parts

- PLC control system with touchscreen HMI

- Automatically displaying devices for trouble, speed, and finished product counting.

- No carton/ skip load and no product/ skip carton control

- Overload protection

- Many options available upon request