The multilane stickpack machine is designed to pack powders; dense, fine, loose and particulate materials, as well as liquids and gels, into stickpack bags to accommodate different bag shapes including pour spouts, tear notches and easy-open systems.

- Home

- VFFS Machines

- Multilane Stickpack Machine Model SBM-ST12

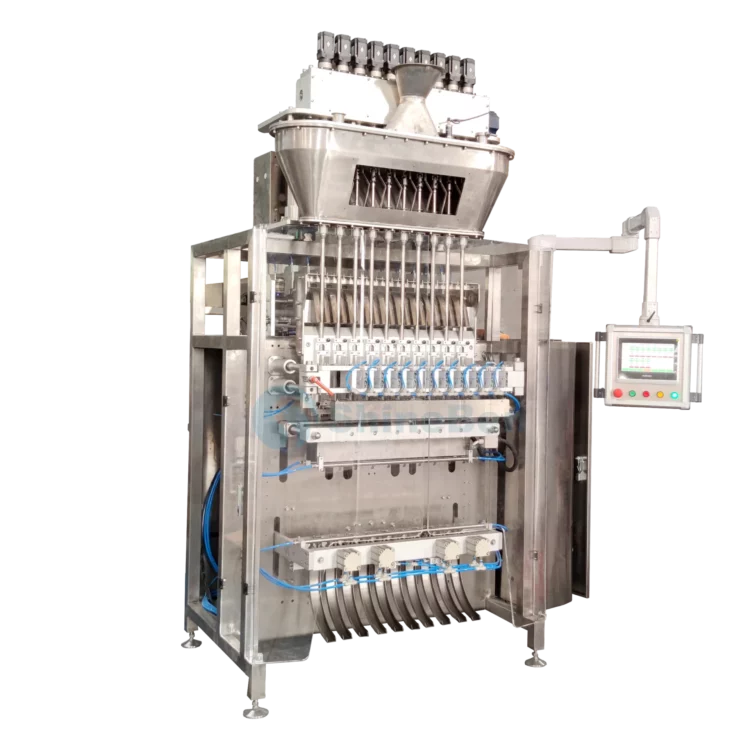

Multilane Stickpack Machine Model SBM-ST12

01 Overview

This machine is designed to pack powders; dense, fine, loose and particulate materials, as well as liquids and gels, into stickpack bags to accommodate different bag shapes including pour spouts, tear notches and easy-open systems.

02 Description

03 Videos

04 Machine Introduction

– Feeding mechanism

Servo motor longitudinal stirring, feeding system, drive bin and material bin isolation in the middle to do sealing treatment, material bin to do slope treatment and add with bulkhead oscillator, add with transverse divider to ensure uniform supply of materials, optional vacuum feeding machine and nitrogen filling device.

– longitudinal sealing mechanism

The longitudinal sealing forming part adopts front and back buckling mechanism and inclined pushing palm sealing mechanism to ensure accurate bag making, independent easy-tear mouth device, which is simpler and more convenient to replace, special surface treatment for forming and sealing part of the mold, which is high temperature resistant, non-stick bag, and ensures that the material is not carbonized.

– Cross-seal mechanism

The cross-sealing mechanism is driven by high precision servo motor, reciprocating film pulling, which has been practiced for many times and adopts oblique mesh pattern to ensure clear pattern, flat and tight sealing. The sealing mechanism is separated from the easy-tear mechanism, which is easier to replace and adjust.

– Cutting knife mechanism

The cutting knife part adopts modular design, imported materials, high precision processing requirements, wear resistance, to ensure that the bag shape is beautiful.

– Cooling mechanism

According to the size of the product bag, standard 3 to 4 cooling institutions to ensure a clean and smooth cut without burr phenomenon.

– Pre-feeding mechanism

Adopt frequency conversion motor drive, according to the packaging speed change automatically adapt to adjust the film feeding speed, to ensure the tension of the package material, to ensure uniform slitting, the synergy of each process consistent.

– Film erection mechanism

The film erection mechanism has automatic tension control, automatic correction function, adapt to a variety of packaging materials, air rising shaft film erection, more convenient replacement, can be equipped with independent ribbon coding and laser coding. Independent film receiving platform, more convenient to replace the coil (frontal film receiving), reduce the waste of packaging materials.

– Temperature control mechanism

The temperature control mechanism adopts modular design, and PLC directly interacts with temperature control, which makes temperature control more accurate and reliable.

05 Equipment Advantages

- Pneumatic drive mechanism design, simple and practical

- Large screen man-machine interface and intelligent PLC control system

- Good visibility of the side opening protective flap, safe operation

- Meet the new GMP/QS certification standard, corrosion resistant, easy to clean

- Various easy-tear options to create a unique packaging style

06 Technical Data

The following is the standard model technical parameters, special requirements and features can be customized.

| Model | SBM-ST12 |

|---|---|

| Multilane | 12 lanes |

| Packaging Speed | 30-60 bags/minute/lane |

| Bag size | 16-140mm width, 40-200mm length |

| Max. film width | 700mm |

| Bag film material | OPP/CPP, OPP/PE, PET/PE, PET/AL/PE, and so on |

| Power supply | AC 380V/50Hz 3Ph, 20kw |

| Machine noise | Less than 80dB |

| Working pressure of compressed air | 0.5-0.8 Mpa |

| Air consumption | 0.9m3/min |

| Machine Frame | SS304 |

| Machine dimension(L×W×H) | 2400mm×1870mm×2100mm |

| Machine Weight | Approx.2500kg |

07 Order Inquiry

Contact Us for a Quote on this Machine

Do you have a specific question? Whether you’re an existing customer or potential new customer to Shineben, please fill out the attached form and we will respond to your request in a timely manner.