A puffed food production line is a specialized setup used for the manufacturing of puffed or expanded food products. It is designed to process raw ingredients and transform them into finished puffed food items. Here are the key components and processes typically found in a puffed food production line:

- Raw Material Handling: The production line starts with the handling of raw materials such as grains, cereals, or other food ingredients. These raw materials are stored, measured, and transferred to the processing equipment.

- Preprocessing: The raw materials may undergo preprocessing steps like cleaning, sorting, and conditioning to ensure their quality and uniformity before further processing.

- Mixing and Blending: The raw materials are mixed and blended in precise proportions to create a homogeneous mixture. This mixture serves as the base for the puffed food product.

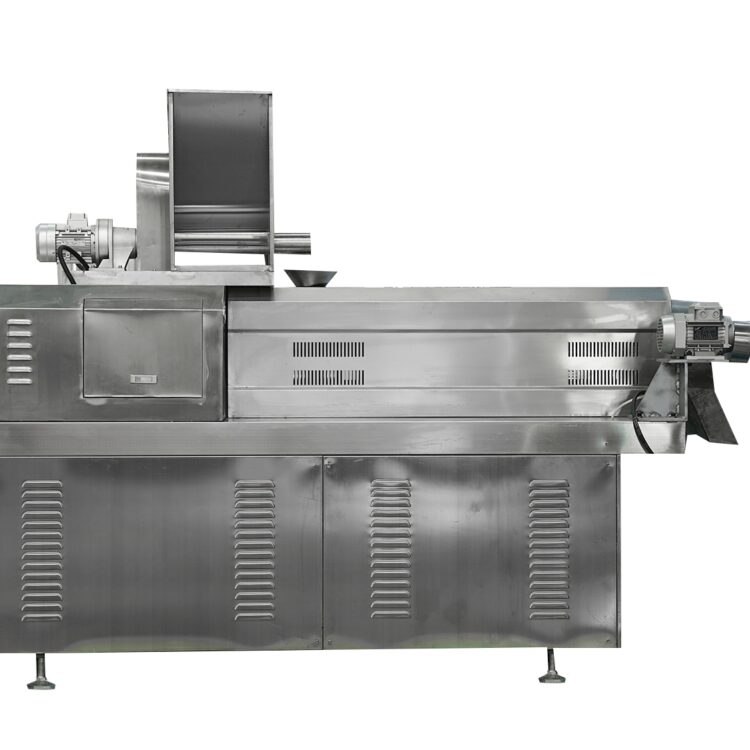

- Extrusion: The mixed material is then fed into an extruder, which uses heat, pressure, and mechanical shear to transform the mixture into a dough-like consistency. This dough is then forced through a die to create the desired shape and size of the puffed food product.

- Puffing or Expansion: The extruded dough passes through a puffing or expansion process, typically involving rapid pressure release, which causes the dough to puff up and expand in volume. This creates the characteristic light and crispy texture of puffed food products.

- Drying and Cooling: The puffed food products may undergo a drying process to remove excess moisture and achieve the desired texture and shelf stability. Cooling processes are also employed to bring down the temperature of the products.

- Seasoning and Packaging: After drying and cooling, the puffed food products are seasoned with various flavors, seasonings, or coatings to enhance their taste. They are then packaged in appropriate containers, such as bags, boxes, or pouches, for distribution and sale.

Advanced production lines may also include additional steps such as frying, flavoring, and quality control inspections to ensure product consistency and safety.