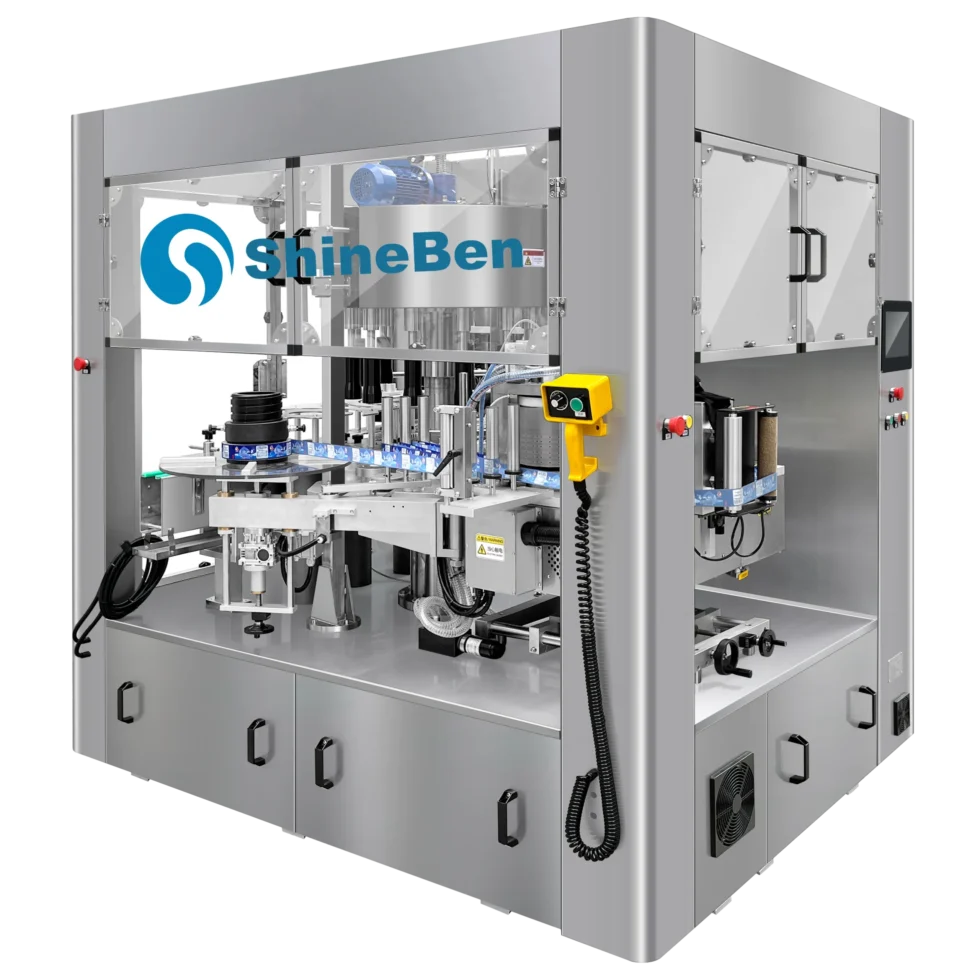

This rotary hot melt glue labeler has a wide range of applications and is suitable for cylindrical containers such as large round or square barrels in industries such as detergents, beverages, mineral water, food, etc. It can label the circumferential surfaces of plastic bottles, glass bottles, and metal cans with OPP film, pearl film, paper-plastic composite film, paper labels, and other materials. Due to the use of non-shrinking materials, the printed patterns on the labels will not deform, ensuring the aesthetic appeal of product packaging, while also significantly reducing packaging material costs.

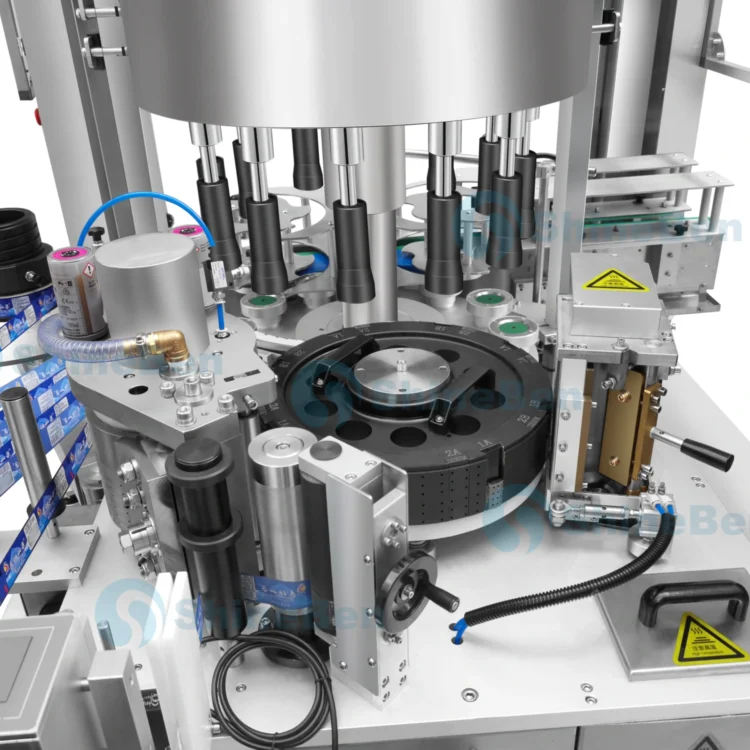

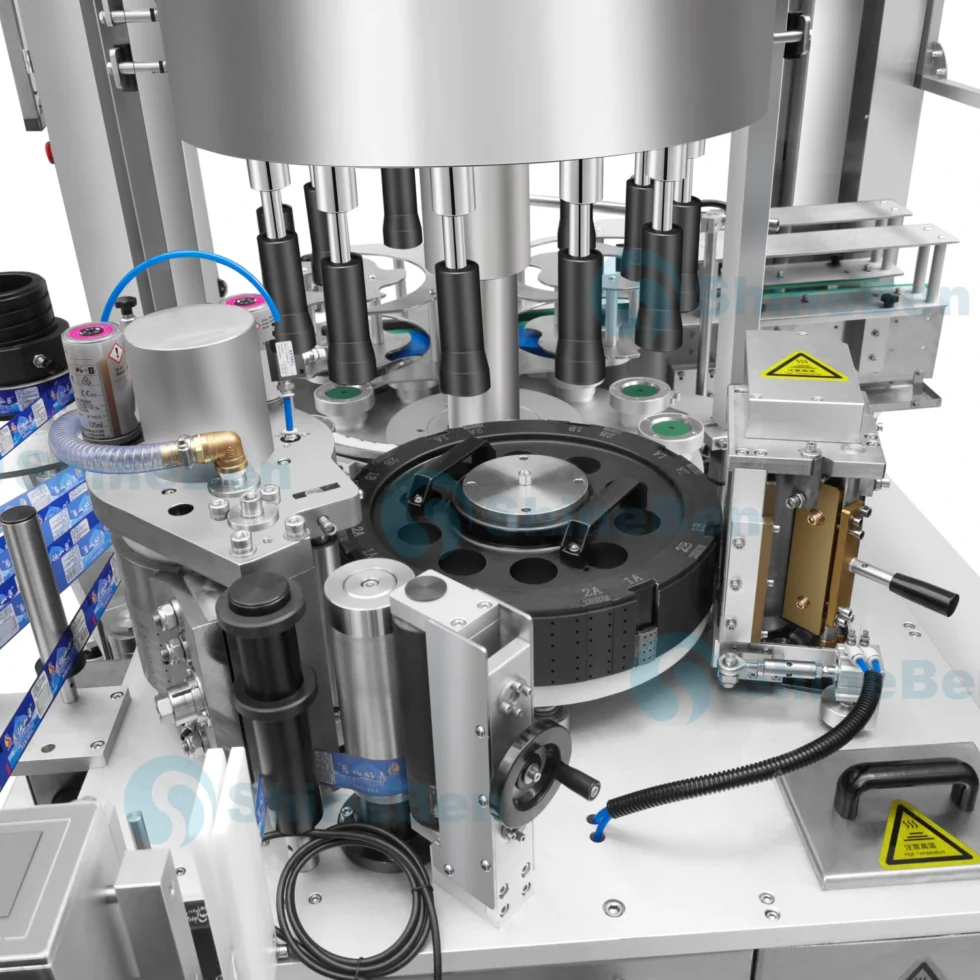

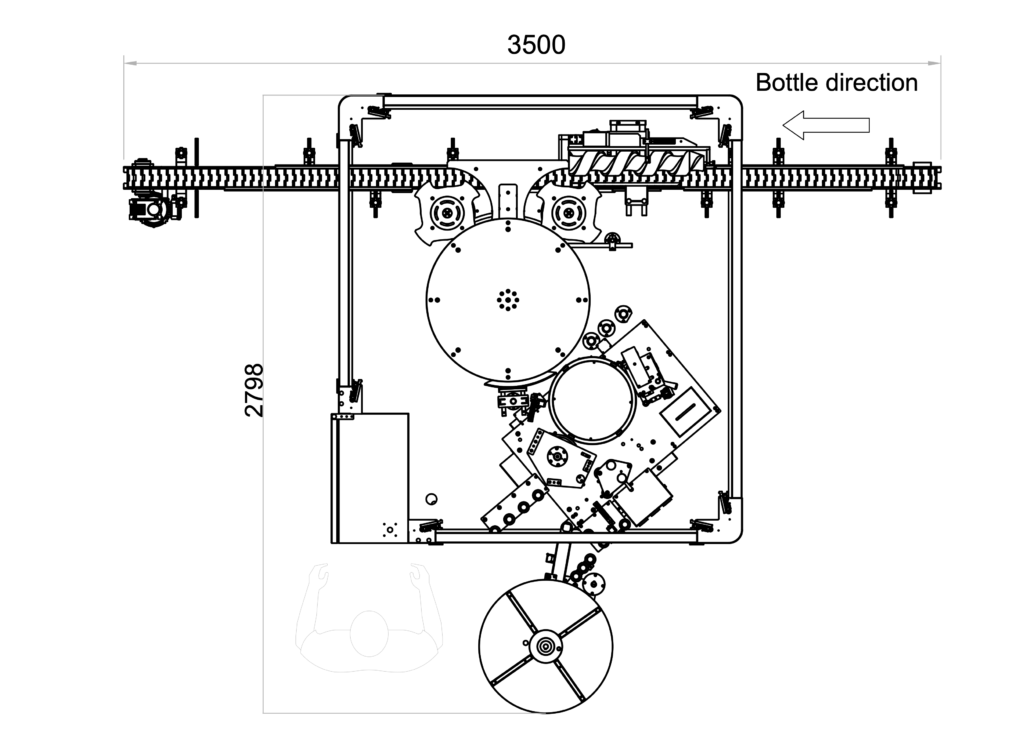

This rotary hot melt glue labeler is a new type of labeling machine designed for labeling large barrel products at a single workstation. Bottles conveyed by the intelligent bottle distributor are pushed into the labeling station by cylinders. The vacuum suction cups for label positioning and the bottle feeding star wheel are precisely calculated, so that when the bottle reaches the labeling station, the adhesive-coated label is perfectly aligned with the labeling position.

When the bottle reaches the optical sensor detection position at the labeling station, the PLC controls the label feeding system for label application. Upon completing a label application cycle, a high-speed cutter severs a label. The use of Schneider ultra-small inertia high-speed servo motors ensures the accuracy and stability of high-speed label application and cutting.

The cut label is transferred to the vacuum suction cups and fed into the adhesive application system. In this part, the system applies adhesive to both ends of the label’s edges. This adhesive application method minimizes the consumption of hot melt glue. When the adhesive-coated label is transferred to the labeling position, it adheres accurately and effectively to the container. As the container rotates during the label transfer process, the label is smoothly and tightly affixed to the bottle. The adhesive strip at the end of the label forms a secure label overlap seal, completing the labeling process.