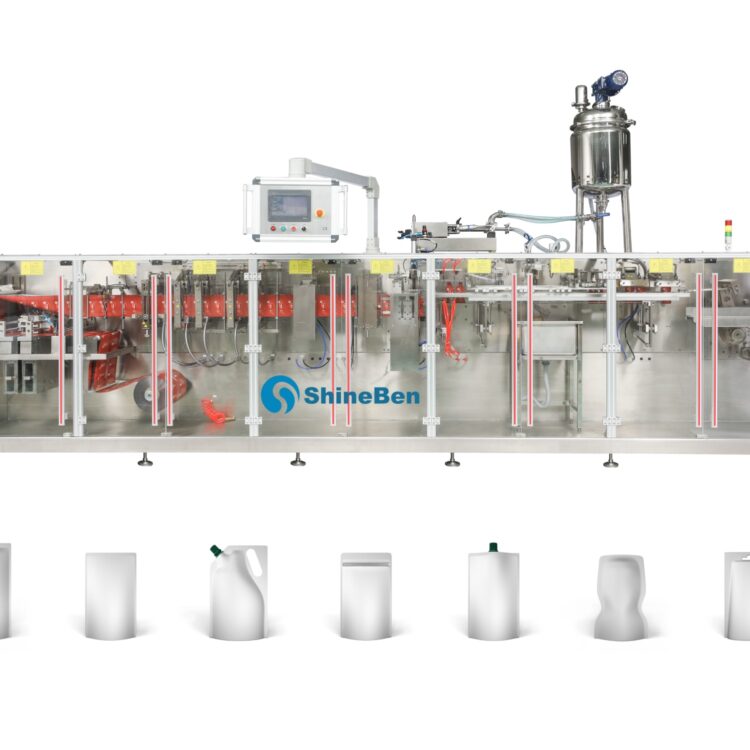

The SBMHD-280DS stand up pouch packing machine is a duplex system, coupled with a twin timing hopper from a multihead weigher or twin dosing system, this machine can run up to 120 pouches per minute. The SBMHD-280DS stand up pouch packing will suit your high speed filling requirements. The Horizontal Fill Form and Seal machine can form both doy pouches and flat bags from a rewind film then fill and seal. The pitch between station is 280mm but as this is a duplex system this can run bags up to 140mm wide. This is perfect for the packing FMCG and only requires an operator to change film instead of manually loading each premade bag.

- Home

- HFFS Machines

- Stand up Pouch Packing Machine SBMHD-280DS

Stand up Pouch Packing Machine SBMHD-280DS

01 Overview

The SBMHD-280DS stand up pouch packing machine is a duplex system, coupled with a twin timing hopper from a multihead weigher or twin dosing system, this machine can run up to 120 pouches per minute.

02 Stand up Pouch Packing Machine Description

03 Pouch Styles

The SBMHD-280DS stand up pouch packing machine makes, fills & seals Doypack, Doypack with zippers, larger Flatpacks, mold-cut shaped stand up pouches, and stand up spout pouches for liquids. This high performer delivers pouches of premium quality of seals and appearance.

04 Videos

05 Features of Stand up Pouch Packing Machine

Servo Technology, Full control of machine operation

The SBMHD Series doypack horizontal packing machines feature a transmission system, which enables for multiple independent axis movements.

This technology substitutes the traditional and standard single cam shaft, and therefore has significantly fewer mechanical parts. The control is provided by means of an intuitive touch screen HMI, facilitating format change-over and adaptability to multiple formats. This is made possible by the servo technology, which enables independent movements of machine parts.

The SBMHD Series doypack packing machines produce pouches with excellent seals, equal to the quality of premade pouches. Moreover, these machines produce pouches with a huge number of designs and shapes for a better product differentiation on the shelf.

Industry leading horizontal packaging machine technology

Pouch width automatic correction system, allows for a productivity up to 10% higher than mechanical HFFS doypack packing machines.

Accessibility for easier maintenance facilitated by the touch screen. Which includes instructions manuals, electronic and pneumatic diagrams.

Little maintenance is required because the SBMHD series machines possess fewer mechanical parts. And its Sanitary construction simplifies the machine.

More Features about the stand up pouch packing machine

Vertical sealing group equipped with motorized adjustment for size, through an intuitive touch screen. By so doing, the Sealing jaws temperature can be individually controlled.

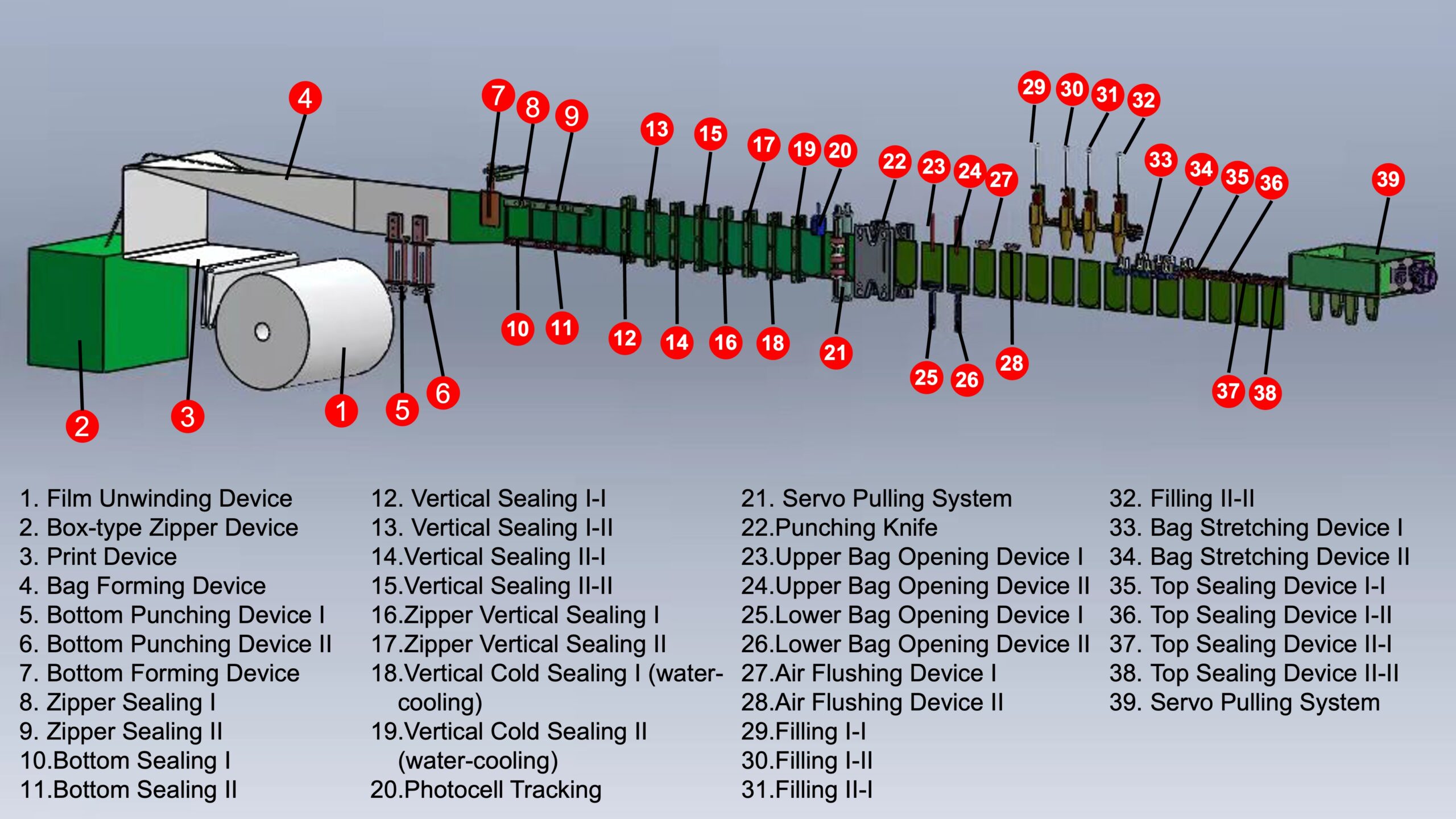

06 Operation Drawing

07 Technical Data

| Parameter | SBMHD-280DS | SBMHD-280DSZ | SBMHD-280DSC |

|---|---|---|---|

| Pouch Type | Doypack, Shaped, Hanging Hole | Doypack, Shaped with Zipper, Hanging Hole | Doypack, Shaped, Spout Pack |

| Packing Material | All kinds of laminated films | All kinds of laminated films | All kinds of laminated films |

| Min Pouch Size(W × L) | 90mm×110mm | 90mm×110mm | 90mm×110mm |

| Max Pouch Size(W × L) | 140mm × 250mm | 140mm × 250mm | 140mm × 250mm |

| Max Volume | 600ml | 600ml | 600ml |

| Max. Packing Speed | 90-120 bags/min | 90-120 bags/min | 90-120 bags/min |

| Number of Filling Station | 2 | 2 | 2 |

| Standard Functions | Date Printing, Output Conveyor | Date Printing, Output Conveyor | Date Printing, Output Conveyor |

| Optional Functions | No-bag-no-fill, Aseptic packing, Antistatic, CIP, Anti-dropping filling | No-bag-no-fill, Aseptic packing, Antistatic, CIP, Anti-dropping filling | No-bag-no-fill, Aseptic packing, Antistatic, CIP, Anti-dropping filling |

| Air Consumption | 400NL/min | 400NL/min | 400NL/min |

| Ambient Temperature | -10°C~55°C | -10°C~55°C | -10°C~55°C |

| Relative Humidity | Below 85%(Non condensation) | Below 85%(Non condensation) | Below 85%(Non condensation) |

| Power Consumption | 13.5 kw | 15.5 kw | 15.5 kw |

| Supply Voltage | 220V, 3 Phase, 50/60Hz | 220V, 3 Phase, 50/60Hz | 220V, 3 Phase, 50/60Hz |

| Dimension(L × W × H) | 9220mm × 1210mm × 1500mm | 9220mm × 1210mm × 1500mm | 9220mm × 1210mm × 1500mm |

| Weight | 3000 kg | 3200 kg | 3200 kg |

08 Options

Filler Options

- Auger Filler ( for powder products)

- Volumetric Cup Filler (for grains)

- Multi-head Weigher (for grains and granular items like chips, candies etc.)

- Piston Pump ( for liquid products)

- Tablet Counting (for tablets)

- Vibrating Filler ( for block items, nails, screws, etc.)

Machine Options

- Hole punch device

- Gas flush device

- Middle capping device

- The shaped bag molding device

- Stand-up pouch former

- Tear notch device

- Zipper application device

- Vacuum station etc. are among many options available

Machine Material Options

- SS304 stainless steel based product contact parts for general food/cosmetics/pharmaceutical industries

- SS316 corrosion-resistant stainless steel based product contact parts for highly corrosive products like salt, chemicals, etc.

Optional Equipment

- Screw elevator/conveyor for automatic continuous feeding of powder products

- Z-bucket elevator for automatic continuous feeding of granular products

- Agitator/mixer for liquid or paste products

- Product counter and stacking belt conveyor

- Extra filler equipment for different powder, granular, liquid, or part type products packaging in a single machine. The choices are: volumetric cup filler, multi-head weigher, piston pump filler, auger filler, and vibrating filler

- Air compressor

- Complete line including Meta Detector, Check Weigher, Boxing or Cartoning Machine, Robot Palletizer, Pallet Wrapping Machines, etc.

09 Order Enquiry

Contact Us for a Quote on the HFFS Stand Up Pouch Packing Machine

Do you have a specific question? Whether you’re an existing customer or potential new customer to Shineben, please fill out the attached form and we will respond to your request in a timely manner.