Vertical Form Fill Seal Machines (VFFS) form bags from film and fill a variety of products such as powders, granules and chips by dropping them vertically in various shapes and types such as candy, coffee beans, frozen foods and snacks. We are experts in the field of filling and offer machines capable of handling zipper bags, flat bags, four-side-seal bags, three-side-seal bags, etc. with gas filling capabilities to achieve the maximum level of value-added packaging to meet customer requirements. Our wide range of products also offers simple and economical models with basic vertical form fill seal machine (VFFS) features, but also with sturdy frame construction made in China.

- Home

- VFFS Machines

- Vertical form fill seal machine SBM-VFFS420

Vertical form fill seal machine SBM-VFFS420

01 Overview

Vertical Form Fill Seal Machines (VFFS) form bags from film and fill a variety of products such as powders, granules and chips by dropping them vertically in various shapes and types such as candy, coffee beans, frozen foods and snacks.

02 Description

03 Application

It is mainly suitable for automatic weighing and packing of granular products such as beans, peanuts, walnuts, star anise, pepper, etc.

04 VFFS Machine Advantages

- Equipment frame is made of 304 stainless steel, in line with food QS and pharmaceutical GMP hygiene standards.

- Equipped with safety protection, in line with enterprise safety management requirements.

Adopt independent temperature control system, accurate temperature control, to ensure beautiful and smooth sealing. - Servo motor film pulling, PLC control, touch screen control, automatic control capability of the whole machine, high reliability and intelligence, high speed and high efficiency.

- Double belt film pulling, film pulling system and color coding control system, can be automatically adjusted by touch screen, easy operation for sealing correction and notching correction.

- Touch screen can store a variety of different products packaging process parameters, when the replacement of products can be used at any time without adjustment.

- The machinery is equipped with a fault display system, which can help troubleshoot in time and reduce the requirements for manual operation.

- A set of equipment to complete the entire packaging process from material conveying, measuring, coding, bag making, filling, sealing, cutting, finished product output.

- It can be made into pillow bag, gusseted bag, euroslot hole bag and chain style bag according to customers’ needs.

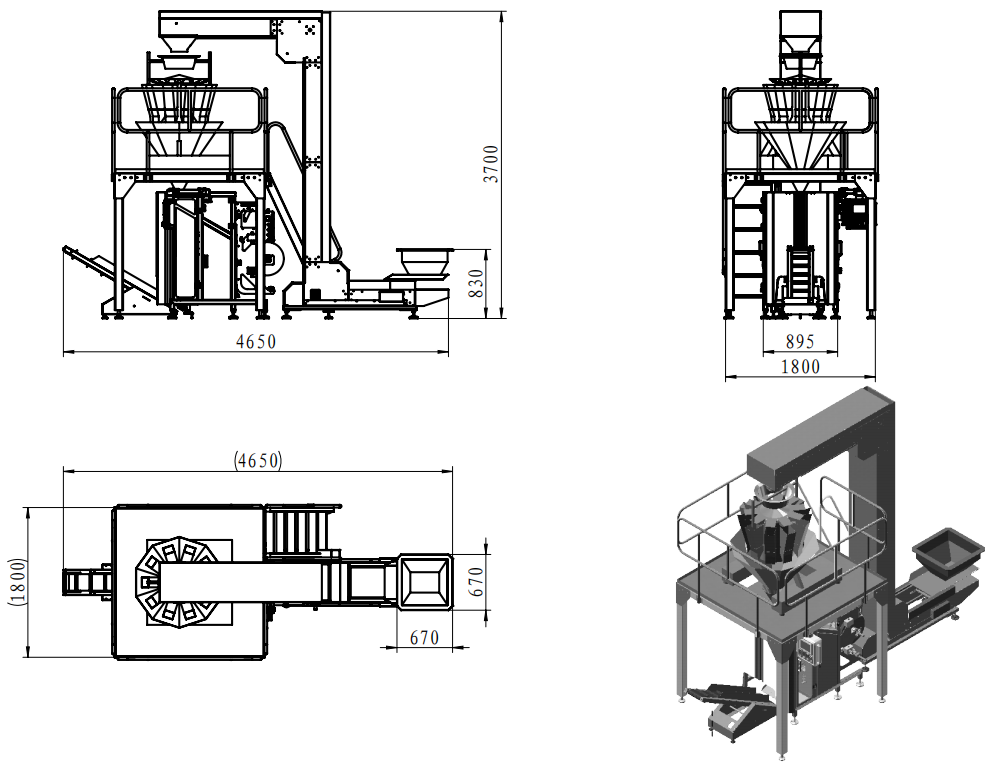

05 VFFS Machine Layout

06 Technical Data

The following is the standard model technical parameters, special requirements and features can be customized.

| Model | SBM-VFFS420 |

|---|---|

| Packaging Speed | 30-40 bags/minute |

| Bag size | 100-250mm width, 100-400mm length |

| Max. film width | 420mm |

| Bag film material | OPP/CPP, OPP/PE, PET/PE and other composite film |

| Measuring method | Automatic weighing |

| Weight range | 200-1500g |

| Weight error | ± 1% (depending on the material) |

| Power supply | AC 380V/50Hz 3Ph, 4.75kw |

| Machine noise | Less than 80dB |

| Working pressure of compressed air | 0.5-0.8 Mpa |

| Air consumption | 0.6m3/min |

| Machine Frame | SS304 |

| Machine dimension(L×W×H) | 4650mm×1800mm×3700mm |

| Machine Weight | Approx.1200kg |

07 Order Inquiry

Contact Us for a Quote on this Machine

Do you have a specific question? Whether you’re an existing customer or potential new customer to Shineben, please fill out the attached form and we will respond to your request in a timely manner.