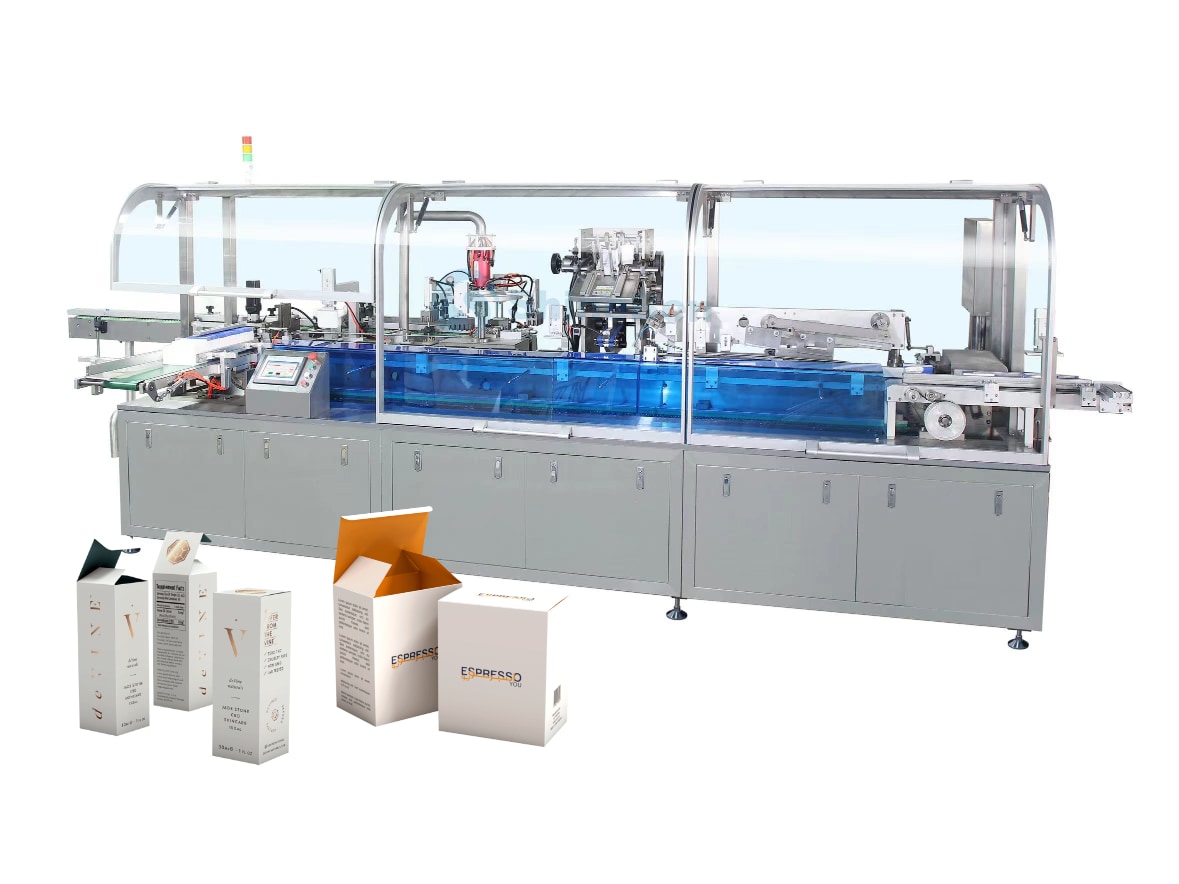

The vertical top load cartoner is a type of packaging machinery used in the manufacturing industry to automate the process of loading products or items into cartons from the top. This type of cartoning machine is commonly used in various industries, including food and beverage, pharmaceuticals, cosmetics, and more, where products need to be efficiently and precisely placed into boxes for packaging.

Here’s how a vertical top load cartoner typically works:

1. Product Feeding: Products are fed into the cartoner’s infeed system, often using a conveyor belt or other means.

2. Carton Magazine: Carton blanks or pre-formed cartons are usually stored in a magazine or hopper. The cartons are typically flat blanks that will be formed into boxes.

3. Carton Forming: The cartoner machine pulls a carton blank from the magazine and forms it into a box.

4. Product Loading: Once the carton is formed, the products are loaded into the open carton from the top. The method of loading may vary depending on the specific design of the cartoning machine and the type of products being packaged. It can involve mechanical arms, vacuum systems, or other mechanisms.

5. Carton Closure: After the products are loaded, the carton is closed and sealed. This can involve various methods such as tucking flaps or gluing.

6. Carton Discharge: The sealed carton is then discharged from the vertical top load cartoner, ready for distribution or further processing.

The SBM-CMV-H80 Vertical top load cartoners are preferred for certain applications because they can handle a wide range of product shapes and sizes, including irregularly shaped items. They are also known for their efficiency, accuracy, and speed in high-volume production environments. Additionally, they offer the advantage of saving space on the production floor, as they have a smaller footprint compared to some other cartoning machines.